(1) The radiator is used for LED street light, but the design of LED connection terminals and heat sinks cannot meet the requirements of GB7000.5 / IEC6598-2-3.

(2) Adopt ordinary road lighting enclosure, and the lighting surface of the lamp adopts matrix LED. Although this design can meet the IP test, the temperature of the lamp will rise due to insufficient ventilation inside the lamp. In the range of 50 ° C to 80 ° C, under such high conditions, the luminous efficiency of the LED will not be very high, and the service life of the LED will be greatly reduced. In fact, there are obviously unreasonable conditions.

(3) The instrument fan is used to distribute the heat sink in the LED and the bulb. The air inlet is designed under the light to prevent rain from entering. The socket is designed around the LED light source. It also effectively prevents rain from entering. In addition, the heat sink and the LED (light source cavity) are not in the same cavity. This design is very good and can pass the IP test requirements of the luminaire. This solution not only solves the heat dissipation problem of LEDs, but also meets the requirements of IP level. But this seemingly good design is obviously unreasonable in practice. Because most street lamps are used in China, the amount of dust in the air is very large, sometimes even to a large extent (such as sandstorms).

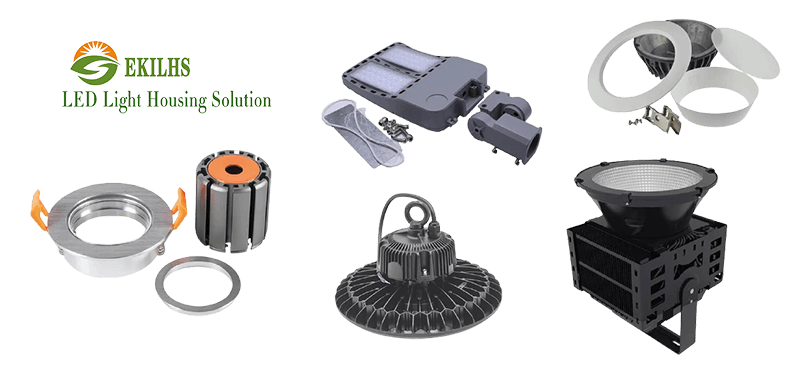

1.Shell Heatsink Design, ( with heat dissipation tendon, separate heatsink and driver box part),

This part according clients , some client more like without Tendon, just will higher cost of housing

A. With Heat Dissipation Tendon & Without heat dissipation tendon

B. Separate heatsink & driver box ( intergration cheap cost but not very good heat dissipation)